TwinCore builds custom AI logistics solutions that embed optimization, forecasting, and predictive logic directly into your operational systems.

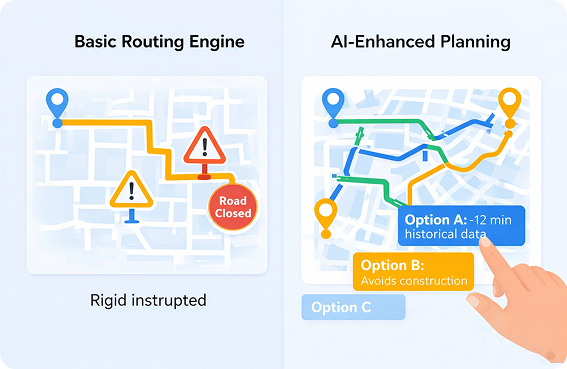

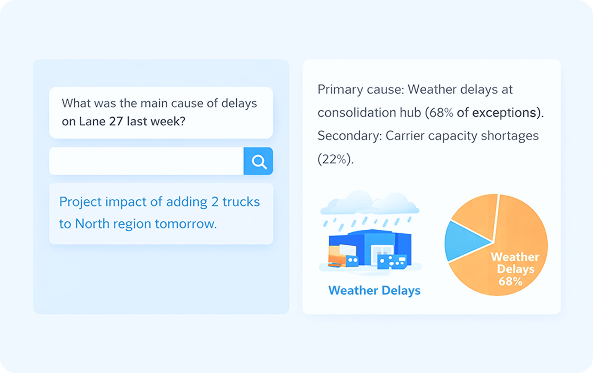

AI initiatives in logistics often remain disconnected from execution, existing as standalone dashboards or analytical experiments without operational impact. Fragmented data across TMS, WMS, telematics, and financial systems limits automation, keeps routing and pricing semi-manual, and delays risk detection. Integrated AI models operating inside your core workflows enable automated planning improvements, reliable forecasts, dynamic pricing logic, and early anomaly detection without introducing another isolated tool.

LinkedIn

LinkedIn

Twitter

Twitter

Facebook

Facebook

Youtube

Youtube